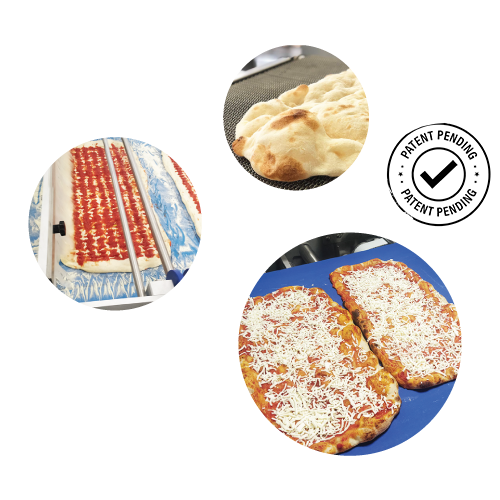

PINSA LINE

Are you ready to innovate and launch yourself into the latest bar and restaurant trends?

Pinsa is just the thing for you!

FEATURES

Maximum output

- Stainless steel structure

- Designed to speed up production

- Respect for the structure of the dough

Options:

- Tomato dosage

- Tomato spreading

- Cheese dispensers

New process

- Reproduction of handmade work

- Suitable for processing dough with very high hydration

high hydration

Maintains unchanged the characteristics of the highly hydrated dough

artisanal

Gentle workmanship that simulates manual labor

cutting-edge

Among the first specific solutions for the production of pinsa

WATCH IT IN ACTION

Would you like to request a free trial?

Contact us! We will be happy to schedule our meeting for a free test and advise you on the best solution for your needs.

TECHNICAL DATA

Components

- Ball positioning tapes

- Chalking

- Pre-rolling section

- Rolling heads

- Possible cheese maker and/or tomato dispenser and automatic panning or freezing/oven spiral loading

Technical data

| Power: | > 10 Kw |

| Compressed air consumption: | > 200 lt/min |

| Production: | starting from 800 pcs/h* |

*production is calculated according to the format

Construction

- Stainless steel carpentry

- Conveyor belts in sanitizable food grade polyurethane

- All parts in contact with the product are compliant for food contact

Encumbrance

| Total dimensions: | Custom project |

| Useful tape: | 600, 800, 1200 mm* |